Products

Contact Us

Address:

15 Wangao nan Road, Xinqian Subdistrict, Huangyan District, Taizhou, Zhejiang

Telephone:

E-mail:

HGE 4-Flute End Mill

Key words: tool

Classification:

Product Details

特点:

1、0.3um ultra fine particles,makes it have both toughness and hardness,high speedand long time cutting could be true.

2、The super lubrication of TXcoating surface,makes the friction coefficient of the coating surface lower cutting resistance and cutting temperature will be greatly reduced;On the basis of the original AICr series coating,adding Si element can effectively increase the toughnessand reduce the residual stress in the coating.Long time cutting can be realized under dry and wetconditions.Compared with traditional coating,it has higher wear resistance and versatility.

3、TX coating is very suitable for cutting most of HRC52 materials, widely used in cutting general carbonsteel,pre-hardened steel(<HRC55) ,stainless steel,copper,acrylic and ect.

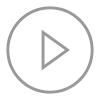

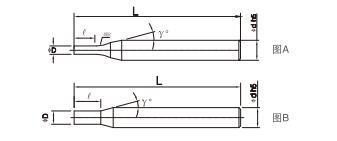

| Model | Blade path | Flute Length | Neck R | Shank cone angle | Length | Shank Diameter | Icon | Stock |

| Type No. | ΦD | l | R | Y/° | L | Φd1 | Pic | |

| HGE4010 0450 | [ | 3 | 4 | 12 | 50 | 4 | A | ▲ |

| HGE4010 0650 | 1 | 3 | 4 | 12 | 50 | 6 | A | ▲ |

| HGE4015 0450 | 1.5 | 4 | - | 11 | 50 | 4 | B | ▲ |

| HGE4015 0650 | 1.5 | 4 | - | 11 | 50 | 6 | B | ▲ |

| HGE4020 0450 | 2 | 6 | - | 11 | 50 | 4 | B | ▲ |

| HGE4020 0650 | 2 | 6 | - | 11 | 50 | 6 | B | ▲ |

| HGE4025 0450 | 2.5 | 8 | - | 11 | 50 | 4 | B | ▲ |

| HGE4025 0650 | 2.5 | 8 | - | 11 | 50 | 6 | B | ▲ |

| HGE4030 0450 | 3 | 8 | - | 11 | 50 | 4 | B | ▲ |

| HGE4030 0650 | 3 | 8 | - | 11 | 50 | 6 | B | ▲ |

| HGE4030 0675 | 3 | 12 | - | 11 | 75 | 6 | B | ▲ |

| HGE4040 0450 | 4 | 11 | - | - | 50 | 4 | B | ▲ |

| HGE4040 0475 | 4 | 15 | - | - | 75 | 4 | B | ▲ |

| HGE4040 0650 | 4 | 11 | - | 11 | 50 | 6 | B | ▲ |

| HGE4040 0675 | 4 | 15 | - | 11 | 75 | 6 | B | ▲ |

| HGE4050 0650 | 5 | 13 | - | 11 | 50 | 6 | B | ▲ |

| HGE4050 0675 | 5 | 18 | - | 11 | 75 | 6 | B | ▲ |

| HGE4060 0650 | 6 | 16 | - | - | 50 | 6 | B | ▲ |

| HGE4060 0660 | 6 | 16 | - | - | 60 | 6 | B | ▲ |

| HGE4060 0675 | 6 | 20 | - | - | 75 | 6 | B | ▲ |

| HGE4060 06100 | 6 | 20 | - | - | 100 | 6 | B | ▲ |

| HGE4080 0860 | 8 | 20 | - | - | 60 | 8 | B | ▲ |

| HGE4080 0875 | 8 | 20 | - | - | 75 | 8 | B | ▲ |

| HGE4080 08100 | 8 | 25 | - | - | 100 | 8 | B | ▲ |

| Model | Blade path | Flute Length | Neck R | Shank cone angle | Length | Shank Diameter | Icon | Stock |

| Type No. | ΦD | l | R | Y/° | L | Φd1 | Pic | |

| HGE4100 1075 | 10 | 25 | 2 | - | 75 | 10 | B | ▲ |

| HGE4100 10100 | 10 | 30 | 2 | - | 100 | 10 | B | ▲ |

| HGE4120 1275 | 12 | 30 | 4 | - | 75 | 12 | B | ▲ |

| HGE4120 12100 | 12 | 35 | 4 | - | 100 | 12 | B | ▲ |

| HGE4140 1475 | 14 | 32 | 4 | - | 75 | 14 | B | ▲ |

| HGE4140 14100 | 14 | 40 | 4 | - | 100 | 14 | B | ▲ |

| HGE4160 16100 | 16 | 45 | 4 | - | 100 | 16 | B | ▲ |

| HGE4160 16150 | 16 | 50 | 4 | - | 150 | 16 | B | ▲ |

| HGE4200 20100 | 20 | 45 | 4 | - | 100 | 20 | B | ▲ |

| HGE4200 20150 | 20 | 55 | 4 | - | 150 | 20 | B | ▲ |

Cutting Parameters

| Material of Work Piece | Carbon Steels, Alloy Steels (HRC35 or less) |

Pre-Hardened Steels |

Hardened Steels (HRC46-55) |

|||||||||

| Type No. |

Spirde speed min |

Feed mm/min |

Ap mm |

Ae mm |

Spirde speed min |

Feed mm/min |

Ap mm |

Ae mm |

Spirde speed min |

Feed mm/min |

Ap mm |

Ae mm |

| HGE4010 | 21780 | 1400 | 0.05 | 0.7 | 19800 | 120 | 0.05 | 0.7 | 18000 | 800 | 0.05 | 0,7 |

| HGE4015 | 18150 | 1680 | 0.05 | 1.05 | 16500 | 1488 | 0.05 | 1.05 | 15000 | 960 | 0.05 | 1.05 |

| HGE4020 | 15125 | 2100 | 0.1 | 1.5 | 13750 | 1860 | 0.1 | 1.5 | 12500 | 1200 | 0.05 | 1.5 |

| HGE4025 | 12100 | 2800 | 0.1 | 1.75 | 11000 | 2480 | 0.1 | 1.75 | 10000 | 1600 | 0.05 | 1.75 |

| HGE4030 | 9680 | 2800 | 0.1 | 2.1 | 8800 | 2480 | 0.1 | 2.1 | 8000 | 1600 | 0.05 | 2.1 |

| HGE4040 | 7865 | 2800 | 0.1 | 2.8 | 7150 | 2480 | 0.1 | 2.8 | 6500 | 1600 | 0.05 | 2.8 |

| HGE4050 | 7260 | 2100 | 0.1 | 3.5 | 6600 | 1860 | 0.1 | 3.5 | 6000 | 1200 | 0.1 | 3.5 |

| HGE4060 | 6050 | 1680 | 0.1 | 4.2 | 5500 | 1488 | 0.1 | 4.2 | 5000 | 960 | 0.1 | 4.2 |

| HGE4080 | 5445 | 1680 | 0,2 | 5.6 | 4950 | 1488 | 2 | 5.6 | 4500 | 960 | 0.1 | 5.6 |

| HGE4100 | 4840 | 1400 | 0.2 | 7 | 4400 | 1240 | 0.2 | 7 | 4000 | 800 | 0.1 | 7 |

| HGE4120 | 4235 | 1400 | 0,2 | 8.4 | 3850 | 1240 | 0.2 | 8.4 | 3500 | 800 | 0.1 | 8.4 |

| HGE4140 | 3630 | 1400 | 0.2 | 9.6 | 3300 | 1240 | 0.2 | 9.6 | 3000 | 800 | 0.1 | 9.6 |

| HGE4160 | 3388 | 1400 | 0.2 | 11.2 | 3080 | 120 | 0.2 | 11.2 | 2800 | 800 | 0.1 | 11.2 |

| HGE4200 | 3025 | 1400 | 0.2 | 14 | 2750 | 1240 | 0.2 | 14 | 2500 | 800 | 0.1 | 14 |

Online message