Products

Contact Us

Address:

15 Wangao nan Road, Xinqian Subdistrict, Huangyan District, Taizhou, Zhejiang

Telephone:

E-mail:

HGXE4L 4-Flute Long Neck End Mill

Key words: tool

Classification:

Product Details

Peculiarity:

1、0.3um ultra fine particles, makes it have both to-ughness and hardness, high speed and long time cutting could be true.

2、The super lubrication of ATX coating surface,makes the friction coefficient of the coating surface lower,cutting resistance and cutting temperature will be greatly reduced;

3、ATX coating is very suitable for cutting the materials of HRC40-55,widely used to the processing of high-precision moulds such as car lamp moulds, mobile phone moulds and hardware moulds, etc.

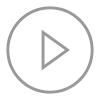

| Model | Blade path | Flute Length | Effective long | First path | Neck R | Shank cone angle | Length | Shank diameter | Icon | Stock |

| Type No. | ΦD | l | l1 | Φd1 | R | Y/° | L | Φd | Pic | |

| HGXE4010L4 0450 | 1 | 0.8 | 4 | 0.94 | 4 | 12 | 50 | 4 | A | ▲ |

| HGXE4010L6 0450 | 1 | 0.8 | 6 | 0.94 | 4 | 12 | 50 | 4 | A | ▲ |

| HGXE4010L8 0450 | 1 | 0.8 | 8 | 0.94 | 4 | 12 | 50 | 4 | A | ▲ |

| HGXE4010L10 0450 | 1 | 0.8 | 10 | 0.94 | 4 | 12 | 50 | 4 | A | ▲ |

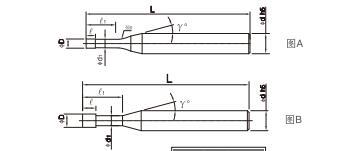

| HGXE4015L6 0450 | 1.5 | 1.2 | 6 | 1.42 | - | 11 | 50 | 4 | B | ▲ |

| HGXE4015L8 0450 | 1.5 | 1.2 | 8 | 1.42 | - | 11 | 50 | 4 | B | ▲ |

| HGXE4015L10 0450 | 1.5 | 1.2 | 10 | 1.42 | - | 11 | 50 | 4 | B | ▲ |

| HGXE4015L12 0450 | 1.5 | 1.2 | 12 | 1.42 | - | 11 | 50 | 4 | B | ▲ |

| HGXE4020L8 0450 | 2 | 1.6 | 8 | 1.9 | - | 11 | 50 | 4 | B | ▲ |

| HGXE4020L10 0450 | 2 | 1.6 | 10 | 1.9 | - | 11 | 50 | 4 | B | ▲ |

| HGXE4020L12 0450 | 2 | 1.6 | 12 | 1.9 | - | 11 | 50 | 4 | B | ▲ |

| HGXE4020L16 0450 | 2 | 1.6 | 16 | 1.9 | - | 11 | 50 | 4 | B | ▲ |

| HGXE4025L10 0450 | 2.5 | 2 | 10 | 2.4 | - | 11 | 50 | 4 | B | ▲ |

| HGXE4025L12 0450 | 2.5 | 2 | 12 | 2.4 | - | 11 | 50 | 4 | B | ▲ |

| HGXE4025L16 0450 | 2.5 | 2 | 16 | 2.4 | - | 11 | 50 | 4 | B | ▲ |

| HGXE4025L20 0450 | 2.5 | 2 | 20 | 2.4 | - | 11 | 50 | 4 | B | ▲ |

| HGXE4030L10 0660 | 3 | 2.4 | 10 | 2.9 | - | 11 | 60 | 6 | B | ▲ |

| HGXE4030L12 0660 | 3 | 2.4 | 12 | 2.9 | - | 11 | 60 | 6 | B | ▲ |

| HGXE4030L16 0660 | 3 | 2.4 | 16 | 2.9 | - | 11 | 60 | 6 | B | ▲ |

| HGXE4030L20 0660 | 3 | 2.4 | 20 | 2.9 | 11 | 60 | 6 | B | ▲ | |

| HGXE4030L25 0675 | 3 | 2.4 | 25 | 2.9 | - | 11 | 75 | 6 | B | ▲ |

| HGXE4040L12 0660 | 4 | 3.2 | 12 | 3.9 | - | 11 | 60 | 6 | B | ▲ |

| HGXE4040L16 0660 | 4 | 3.2 | 16 | 3.9 | - | 11 | 60 | 6 | B | ▲ |

| HGXE4040L20 0660 | 4 | 3.2 | 20 | 3.9 | - | 11 | 60 | 6 | B | ▲ |

| HGXE4040L25 0675 | 4 | 3.2 | 25 | 3.9 | - | 11 | 75 | 6 | B | ▲ |

| HGXE4040L30 0675 | 4 | 3.2 | 30 | 3.9 | - | 11 | 75 | 6 | B | ▲ |

Cutting Parameters

| Material of Work Piece | Carbon Steels, Alloy Steels (HRC35 or less) |

Pre-Hardened Steels |

Hardened Steels (HRC46-55) |

||||||||||

| Type No. |

Spirde speed min |

Feed mm/min |

Ap mm |

Ae mm |

Spirde speed min |

Feed mm/min |

Ap mm |

Ae mm |

Spirde speed min |

Feed mm/min |

Ap mm |

Ae mm |

|

| 4 | 25000 | 2200 | 0.055 | 0.6 | 22000 | 1400 | 0.045 | 0.5 | 17600 | 1120 | 0.036 | 0,4 | |

| HGXE4010L | 6 | 20000 | 1600 | 0.045 | 0.6 | 18000 | 1000 | 0.035 | 0.5 | 14400 | 800 | 0.028 | 0.4 |

| 8 | 18000 | 1400 | 0.035 | 0.6 | 15000 | 800 | 0.025 | 0.5 | 12000 | 640 | 0.02 | 0.4 | |

| 10 | [6000 | 1200 | 0.025 | 0.6 | 1000 | 700 | 0.018 | 0.5 | 11200 | 560 | 0.0144 | 0.4 | |

| 6 | 20000 | 2400 | 0.08 | 0.9 | 16000 | 1440 | 0.07 | 0.75 | 12800 | 1152 | 0.056 | 0,6 | |

| HGXE4015L | 8 | 18000 | 2000 | 0.07 | 0.9 | 14000 | 1160 | 0.06 | 0.75 | 11200 | 928 | 0.048 | 0.6 |

| 10 | 16000 | 1700 | 0.06 | 0.9 | 13000 | 1040 | 0.05 | 0.75 | 104)0 | 832 | 0.04 | 0.6 | |

| 12 | 14000 | 1400 | 0.05 | 0.9 | 12000 | 900 | 0.04 | 0.75 | 9600 | 720 | 0.032 | 0.6 | |

| 8 | 16000 | 2600 | 0.11 | 1.2 | 13000 | 1600 | 0.09 | 1 | 10400 | 1280 | 0.072 | 0.8 | |

| HGXE4020L | 10 | [6000 | 2400 | 0.1 | 1.2 | 13000 | 1500 | 0.08 | 1 | 10400 | 1200 | 0.064 | 0.8 |

| 12 | 14000 | 2000 | 0.09 | 1.2 | 12000 | 1300 | 0.07 | 1 | 9600 | 1040 | 0.056 | 0.8 | |

| 16 | 12000 | 1600 | 0.07 | 1.2 | 10000 | 1000 | 0.05 | 1 | 8000 | 800 | 0.04 | 0.8 | |

| 10 | 13000 | 2600 | 0.14 | 1.5 | 11000 | 1600 | 0.11 | 125 | 8800 | 1280 | 0.088 | 1 | |

| HGXE4025L | 12 | 13000 | 2400 | 0.13 | 1.5 | 11000 | 750 | 0.1 | 1.25 | 8800 | 600 | 0.08 | 1 |

| 16 | 11000 | 1800 | 0.1 | 1.5 | 9000 | 1100 | 0.07 | 125 | 7200 | 880 | 0.056 | 1 | |

| 20 | 9000 | 1400 | 0.08 | 1.5 | 7000 | 800 | 0.05 | 1.25 | 5600 | 640 | 0.04 | 1 | |

| 10 | 11000 | 2800 | 0.18 | 1.8 | 9000 | 1800 | 0,14 | 1.5 | 7200 | 1440 | 0.112 | 1.2 | |

| HGXE4030L | 12 | 11000 | 2600 | 0.16 | 1.8 | 9000 | 1600 | 0.12 | 1.5 | 7200 | 1280 | 0.096 | 1.2 |

| 16 | 10000 | 2000 | 0.12 | 1.8 | 8000 | 1200 | 0.09 | 1.5 | 6400 | 960 | 0.072 | 1.2 | |

| 20 | 9000 | 1600 | 0.1 | 1.8 | 7000 | 900 | 0.07 | 1.5 | 5600 | 720 | 0.056 | 1.2 | |

| 25 | 8000 | 1400 | 0.08 | 1.8 | 6000 | 760 | 0.06 | 1.5 | 4800 | 608 | 0.048 | 1.2 | |

| 12 | 8000 | 3000 | 0.3 | 2.4 | 6000 | 1700 | 0.25 | 2 | 4800 | 1360 | 0.2 | 1.6 | |

| 16 | 8000 | 2800 | 25 | 2.4 | 6000 | 1600 | 0.2 | 2 | 4800 | 1280 | 0.16 | 1.6 | |

| HGXE4040L | 20 | 8000 | 2600 | 0.2 | 2.4 | 6000 | 1460 | 0.15 | 2 | 4800 | 1168 | 0.12 | 1.6 |

| 25 | 7000 | 2200 | 0.15 | 2.4 | 5000 | 1200 | 0.1 | 2 | 4000 | 960 | 0.08 | 1.6 | |

| 30 | 7000 | 2000 | 0.12 | 2.4 | 5000 | 1080 | 0.08 | 2 | 4000 | 864 | 0.064 | 1.6 | |

Online message